- Learn about Asada Mesh !

- Click on the buttons and find out

how Asada Mesh has been supporting your life!!

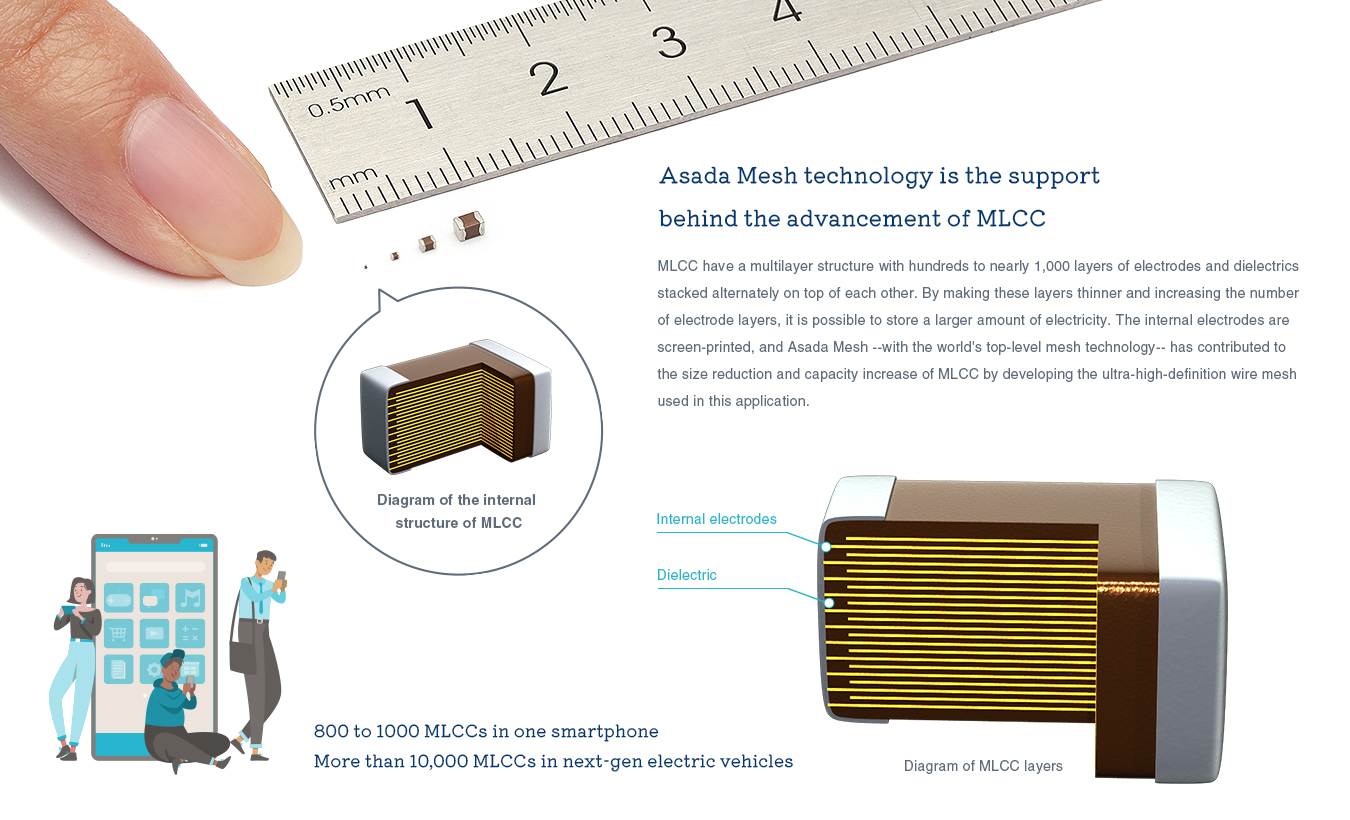

Screen printing, which requires our mesh, has high printing versatility that enables you to print lines accurately down to the micron range on various materials.

As a legitimate printing technology for electronic products, screen printing has been supporting a number of manufacturing industries,

from semiconductor chips to smartphone electric circuits.

Our wire mesh is indispensable in screen printing. As a world number one in weaving technology

we contribute to industries domestic and abroad with our unique know-how based on deep understanding of the screen printing process.

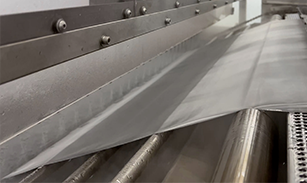

Introduction to the stainless steel mesh manufacturing process!

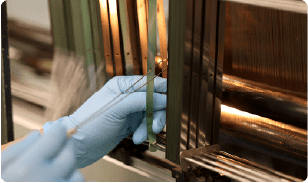

We ensure that each employee is thoroughly aware of quality control.

We have introduced a variety of inspection equipment and pay keen attention to the manufacturing environment.

Let's take a look at the secrets behind the reliability of the Asada Mesh brand.

At each entry of the factory, there is an air shower to make sure the manufacturing environment remains clean

All wires are inspected for wire diameter, surface quality, and mechanical properties according to our own strict standards. Only those materials that pass the inspection are allowed to proceed to the next process.

※The process will vary depending on customer needs.

Since our foundation over 80 years ago, our philosophy has always been “Supremacy of Quality”

. We have anticipated the changing times and the changing needs of society; we have surpassed the future.

Asada Mesh will continue to strive to stay ahead of the times and develop new mesh,

to introduce a variety of possibilities to the world, and furthermore,

to be a company of prestige by fulfilling our social responsibilities

and sincerely committing ourselves to corporate innovation.

Mesh only we can make

— it supports the world.