Specification

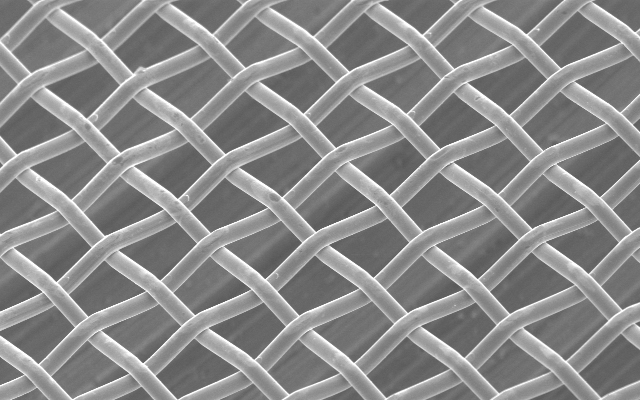

| SPEC | MESH COUNT |

WIRE DIA. (mm) |

SIEVE SIZE (mm) |

OPENING RATE |

THICKNESS(μm) | |||

|---|---|---|---|---|---|---|---|---|

| NORMAL | Calender | |||||||

| SOFT | MIDDLE | HEAVY | ||||||

| UHS-520/11 | 520 | 0.011 | 0.038 | 60% | 26 ± 3 | 21 ± 2 | 17 ± 1 | 11 ± 1 |

| HS-R-500/13 | 500 | 0.013 | 0.038 | 55% | 29 ± 3 | 24 ± 2 | 21 ± 1 | 17 ± 1 |

| SHS-430/13 | 430 | 0.013 | 0.046 | 61% | 29 ± 3 | 24 ± 2 | 21 ± 1 | 17 ± 1 |

| SHS-R-400/16 | 400 | 0.016 | 0.048 | 56% | 36 ± 3 | 25 ± 2 | 21 ± 1 | 15 ± 1 |

| SHS-380/14 | 380 | 0.014 | 0.053 | 62% | 32 ± 2 | 26 ± 2 | 20 ± 1 | 14 ± 1 |

| SHS-360/16 | 360 | 0.016 | 0.055 | 60% | 36 ± 3 | 32 ± 2 | 21 ± 1 | 16 ± 1 |

| SHS-325/16 | 325 | 0.016 | 0.062 | 63% | 35 ± 3 | 32 ± 2 | 20 ± 1 | 18 ± 1 |

| SHS-290/20 | 290 | 0.020 | 0.068 | 60% | 45 ± 3 | 36 ± 2 | 30 ± 1 | 20 ± 1 |

| HS-360/16 | 360 | 0.016 | 0.055 | 60% | 36 ± 3 | 32 ± 2 | 20 ± 1 | 16 ± 1 |

| HS-325/16 | 325 | 0.016 | 0.062 | 63% | 35 ± 2 | 32 ± 2 | 20 ± 1 | 17 ± 1 |

| HS-290/20 | 290 | 0.020 | 0.068 | 60% | 45 ± 2 | 36 ± 2 | 30 ± 1 | 20 ± 1 |

| HS-250/20 | 250 | 0.020 | 0.082 | 65% | 44 ± 2 | 37 ± 2 | 30 ± 1 | 18 ± 1 |

| HS-230/25 | 230 | 0.025 | 0.085 | 60% | 55 ± 2 | 40 ± 2 | 30 ± 2 | 27 ± 1 |

Scroll Side