Clogging Reduced Dramatically

in Special Opening Shape Sieving Mesh

- Sieve / Filter

- Technical Information-03

In the process of fine particle sieving, clogging of mesh openings is the leading reason for falling sieving accuracy.

In order to solve this issue, different measures are taken, for example, using special sieving machines or applying treatment to the surface of the screen.

Stainless steel wire mesh, compared to other mesh, has high rigidity. Therefore we can produce specialty mesh with a high opening ratio, or any other unique weaving style.

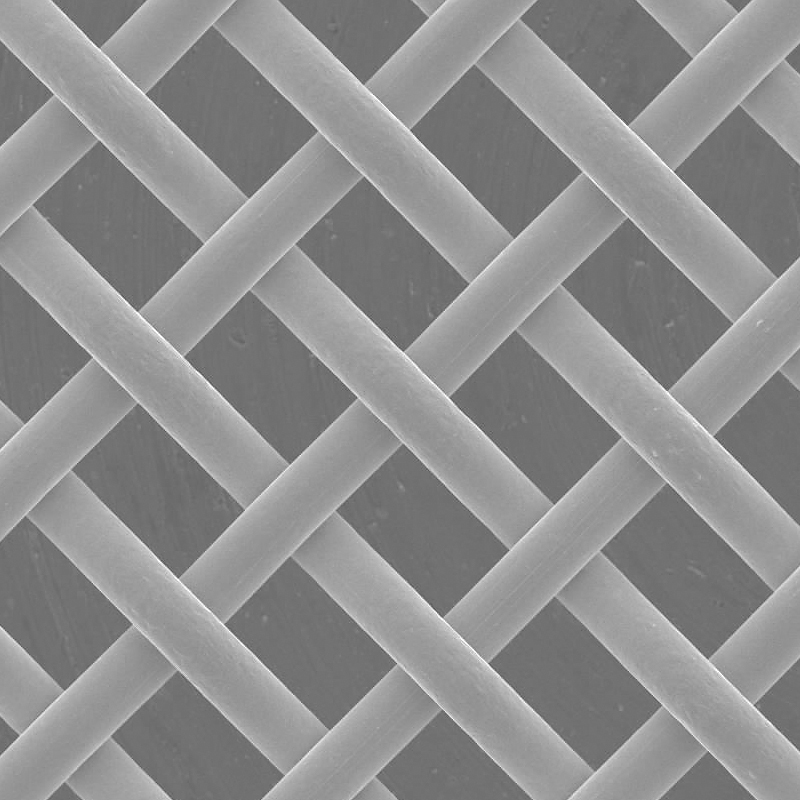

RO-Sieve is a stainless mesh that has been woven to have oblong openings rather than the usual square shape. This mesh is especially useful in sieving round particles because the oblong shape reduces the points of contact between the wire and the particles.

Additionally, because RO-Sieve uses fewer weft wires and therefore has a lower mesh count, it has a higher opening ratio than plain weave mesh of the same count, and because it can be made with thicker wires, it is also stronger and more durable.

Difference of opening

Oblong Opening

| SPEC | OPENING (mm) |

MESH COUNT | WIRE DIA. (mm) |

OPENING RATE |

|---|---|---|---|---|

| RO-16/20 tw | 0.016 × 0.020 | 795 × 700 | 0.016 | 27.7% |

| RO-20/24 tw | 0.020 × 0.024 | 635 × 577 | 0.020 | 37.4% |

| RO-25/32 tw | 0.025 × 0.032 | 500 × 445 | 0.025 | 28.1% |

| RO-25/36 tw | 0.025 × 0.036 | 500 × 416 | 0.025 | 29.5% |

| RO-25/40 tw | 0.025 × 0.040 | 500 × 392 | 0.025 | 30.8% |

| RO-38/61 tw | 0.038 × 0.061 | 374 × 279 | 0.030 | 41.8% |

| RO-45/53 | 0.045 × 0.053 | 330 × 300 | 0.032 | 36.4% |

| RO-45/72 | 0.045 × 0.072 | 330 × 244 | 0.032 | 40.5% |

| RO-43/41 tw | 0.043×0.041 | 325 × 332 | 0.035 | 29.7% |

| RO-60/62 tw | 0.060×0.062 | 250 × 248 | 0.040 | 36.7% |

通常の平織メッシュ

| SV-26/25tw | 0.025×0.025 | 500×500 | 0.025 | 25.8% ★2 |

|---|

振動ふるい機による処理能力比較検証

Verification

We compared the sieving accuracy of basic mesh and RO-Sieve Mesh using a JIS standard round particle sample.

Result

Becasue there was so little clogging, especially at the begining, RO-Sieve performed with high efficiency.