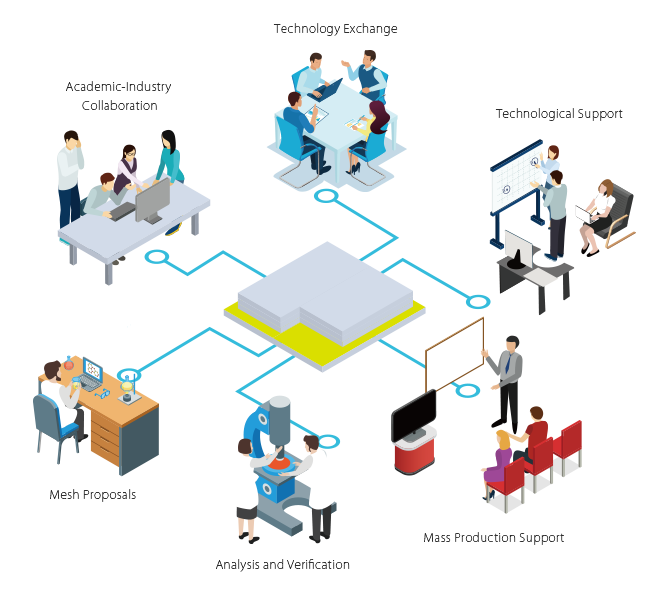

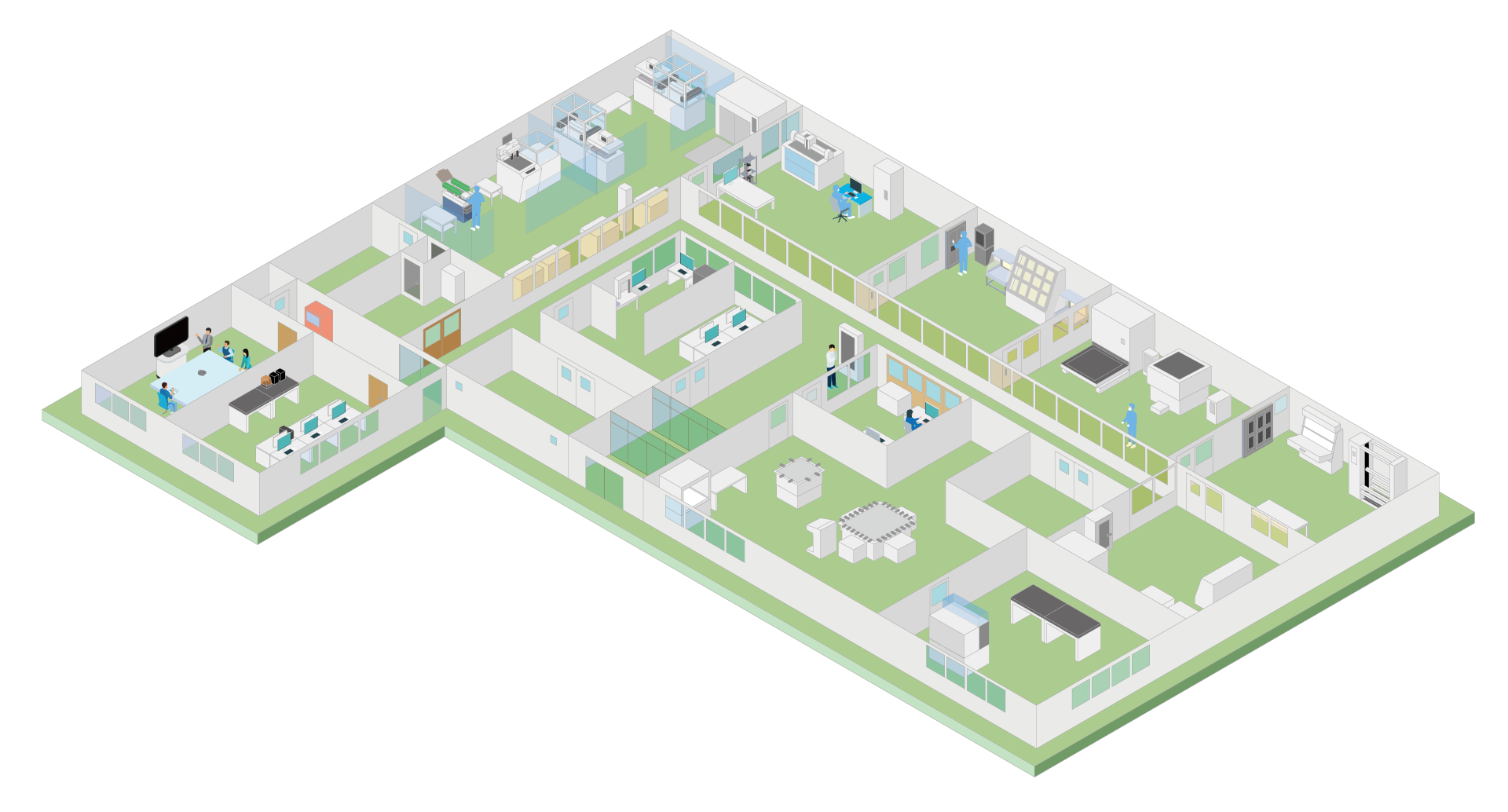

Contributing to innovation and the creation of new technologies by cultivating a relationship between people from various fields

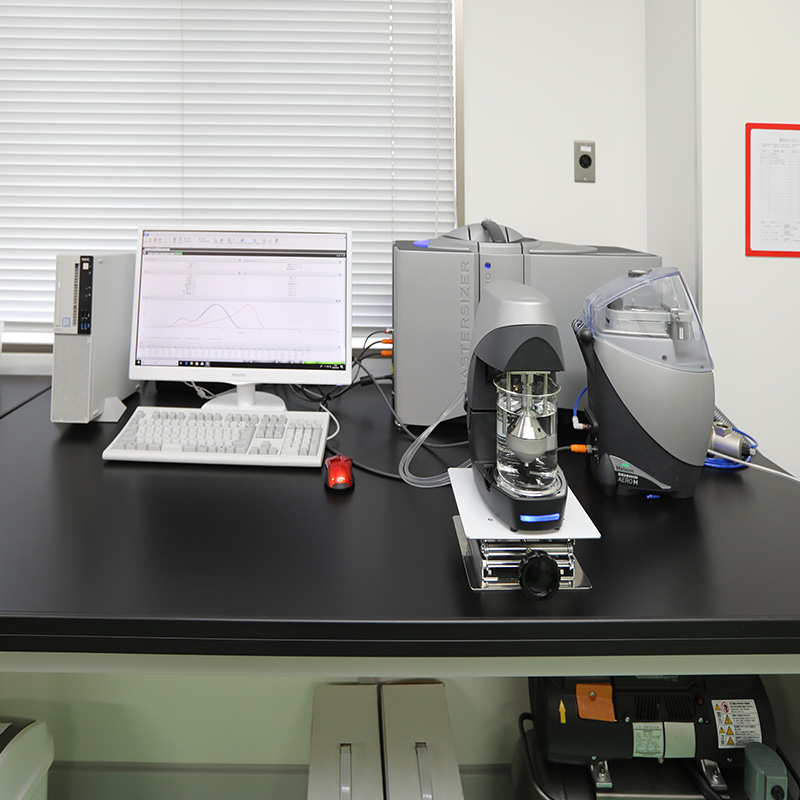

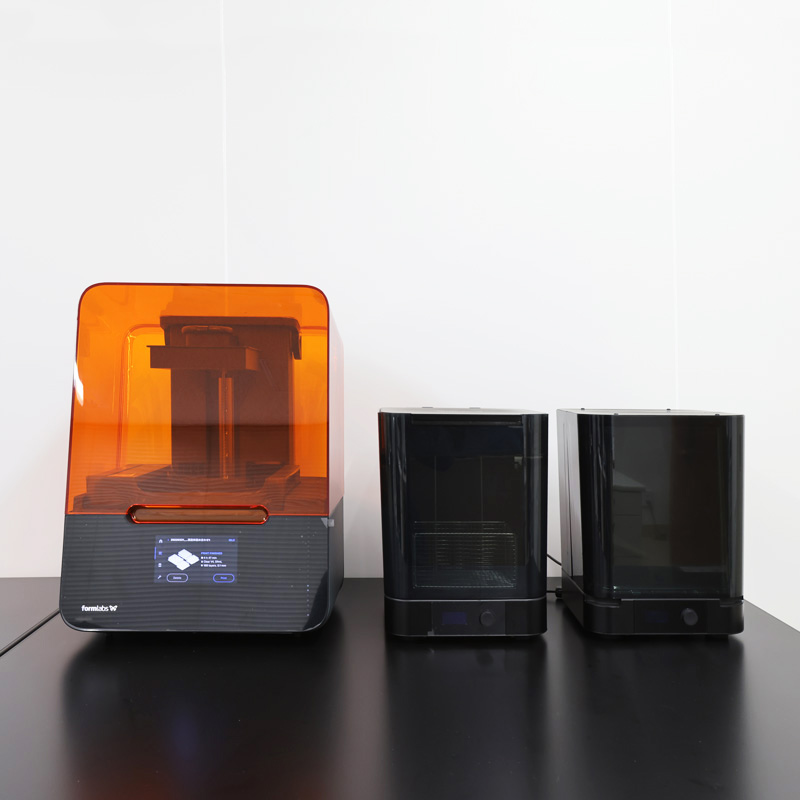

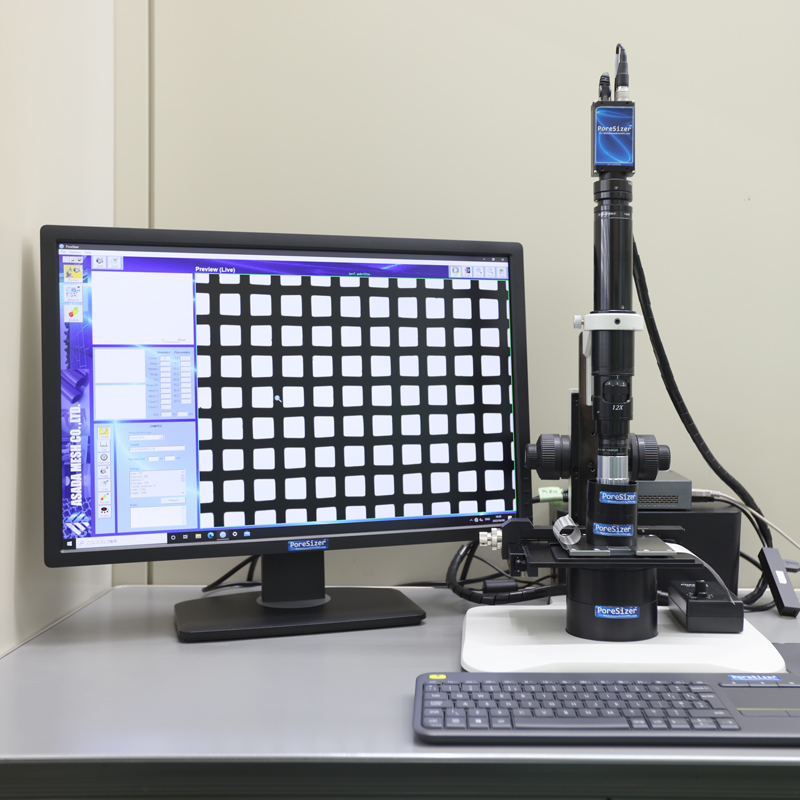

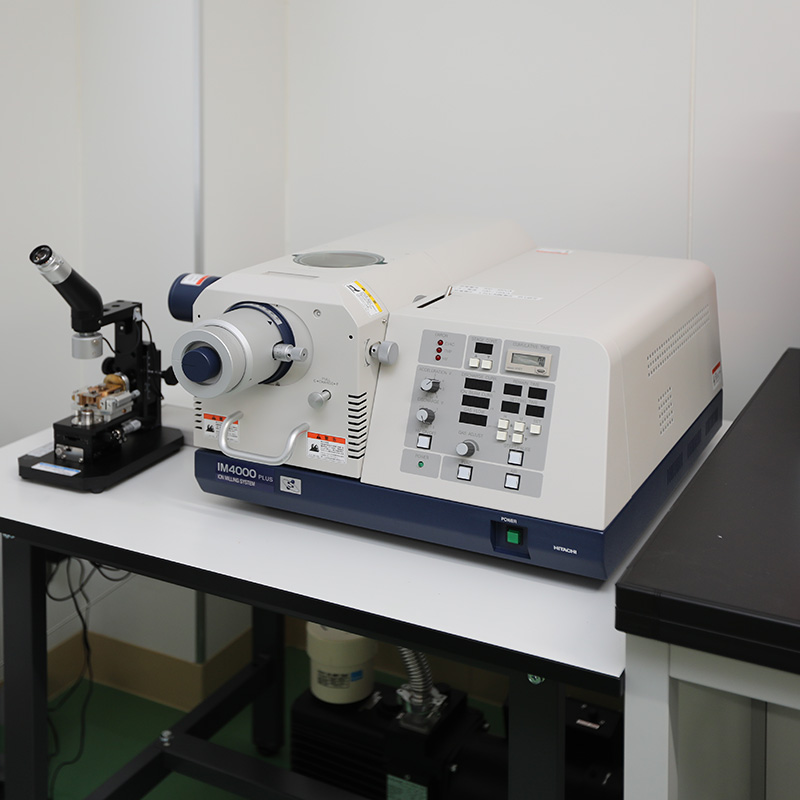

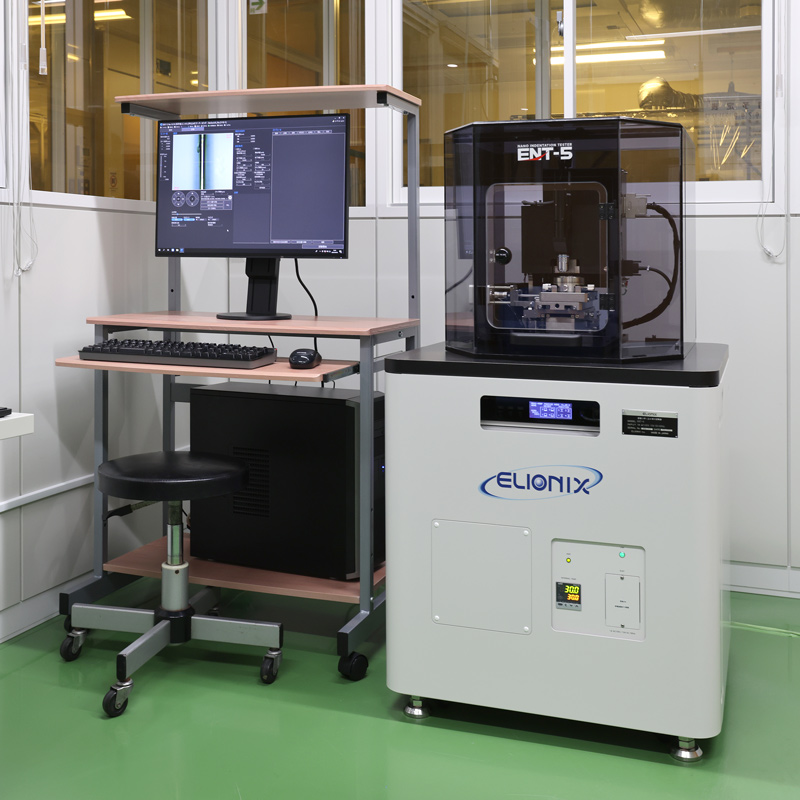

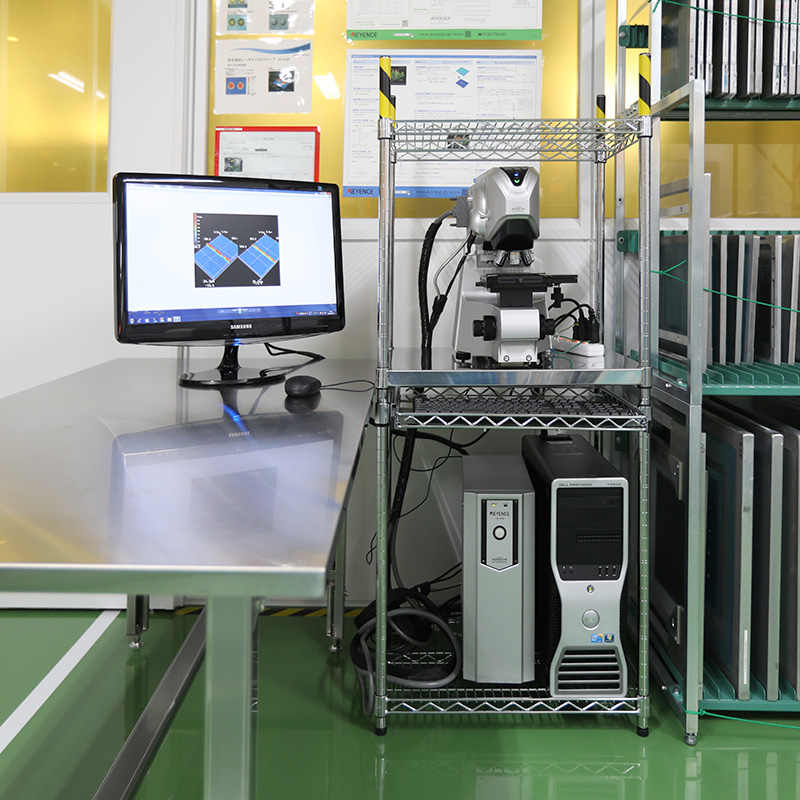

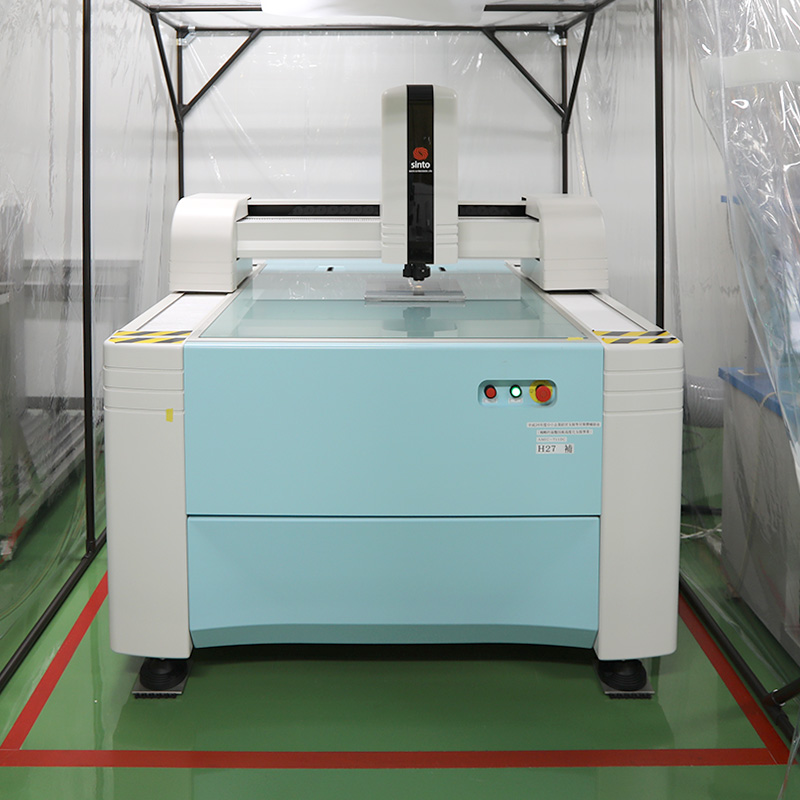

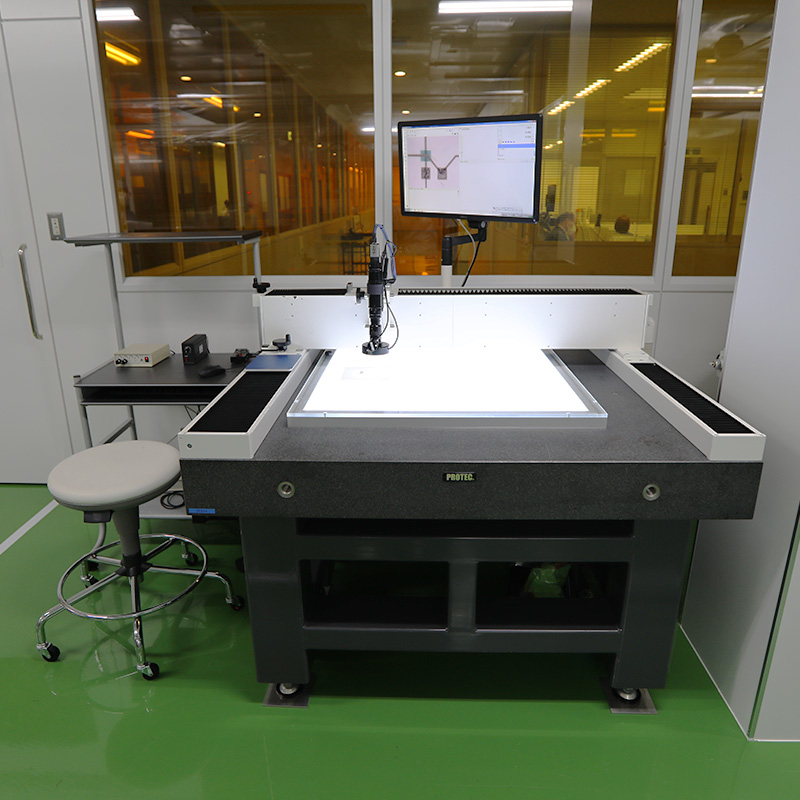

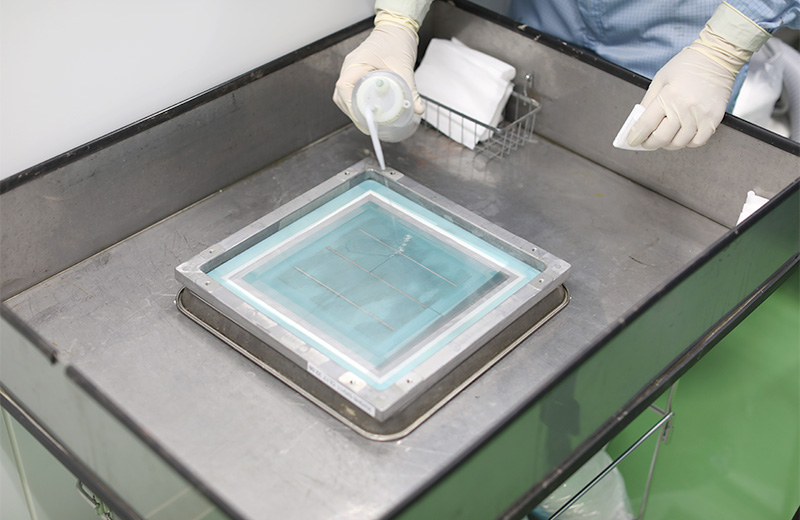

Open Innovation Hub (OIH), is our research and development facility which was established with the aim to work together with our customers to find new value in mesh technology.At OIH we have analytical equipment and other machines related to screen printing and sieving. Our aim is for it to be a technological “hub” for all customers who use stainless steel mesh.