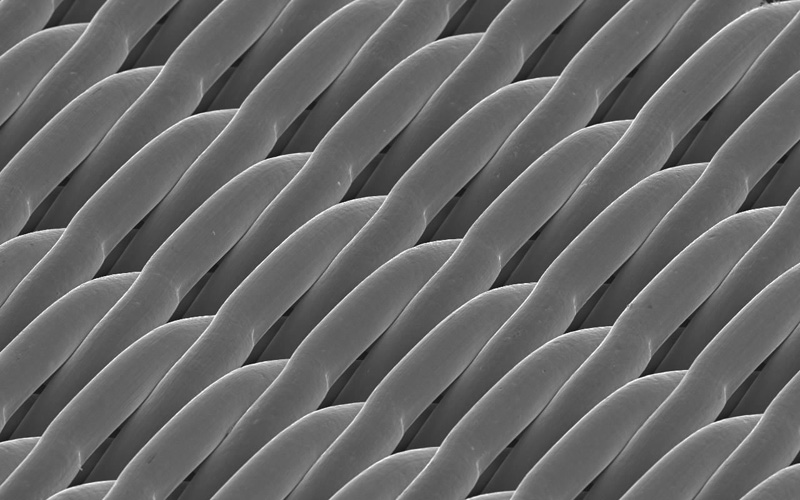

Product Introduction

Asada Mesh’s fine mesh is used worldwide in state-the-art IT development, and contributes greatly to the realization of these discoveries.

Screen Printing

ASADA MESH provides Technical information about to promote the latest Screen Printing Technology. We are convinced that “A-Standard” is useful for the beginners of screen printing and engineers planning to restructure the manufacturing processes.

Technical Information

Asada Mesh has been sharing basic information relating to screen printing to encourage the universal of screen printing technology. We strongly hope to help those just starting in screen printing, as well as those considering restructuring the process, achieve a perfect print.

The Many Roles of Screen Mesh

An introduction to the many roles that “screen mesh” takes in supporting the mechanisms of screen printing.

The Basics of Screen Mesh Printing

For achieving the finest level of printing, we measure everything from mesh materials s to the specifications of the print to our Asada A standard.

High Resolution Printing

If high density paste screen printing can As we use finer mesh, the image of the print will be improved.

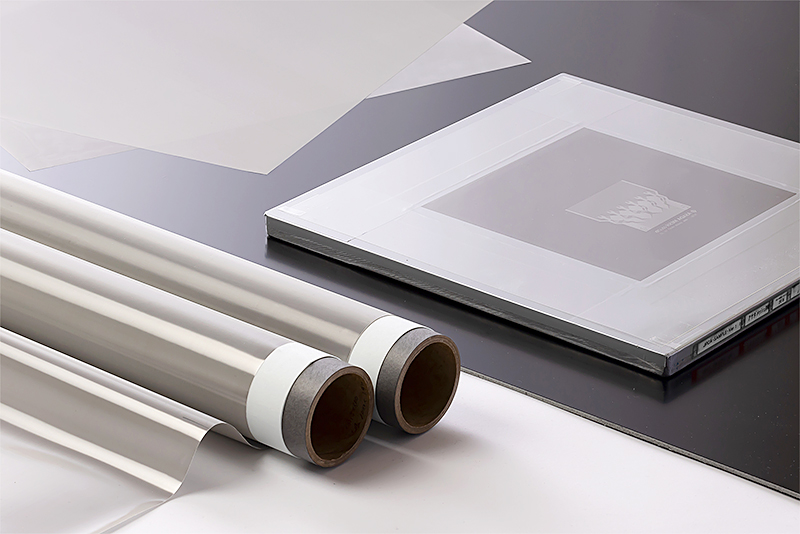

Product Information

Our Products for Screen Printing are categorized as Standard, Hardmesh, Supermesh, 3D-mesh and Ultra-Hard mesh. They have their own mesh count, wire diameter, thickness, strength so that it can be selected depending on customers’ needs or printing applications.

Future Development of Finer and Higher Strength Screen Meshes

There was a time when Silk was actually used as a screen mesh hence the expression “Silk Screen Printing” begun to be used, Today, Screen Printing is adopted to produce various Electronics Products such as Multi Layered Ceramic Capacitor, Photovoltaic and Touch Panel. The demand for finer and stronger meshes continues to push Asada Mesh to develop newer materials to fill the needs of our loyal Customers. Stainless Steel Wire Mesh is necessary to print finer and more accurate printing images. “We will continue to develop finer and stronger metal meshes to help advance Screen Printing Technology”.

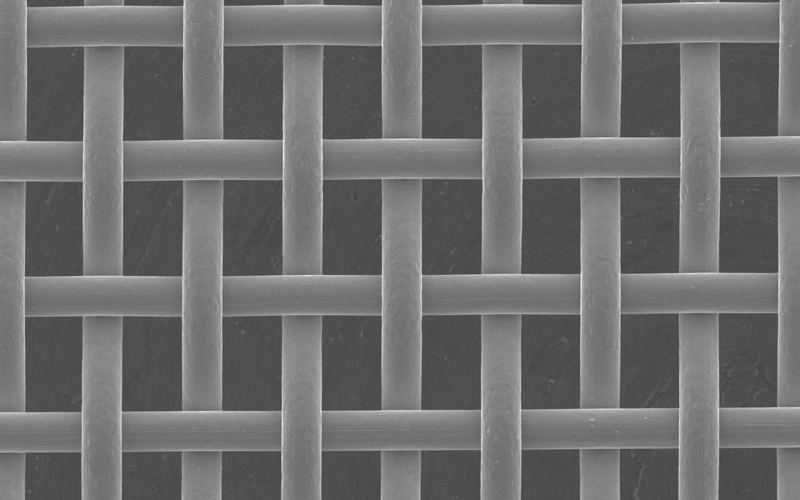

As a standard series mesh for screen printing, it’s has been adopted for wide use such as fine line or thin deposit printing for MLCC.

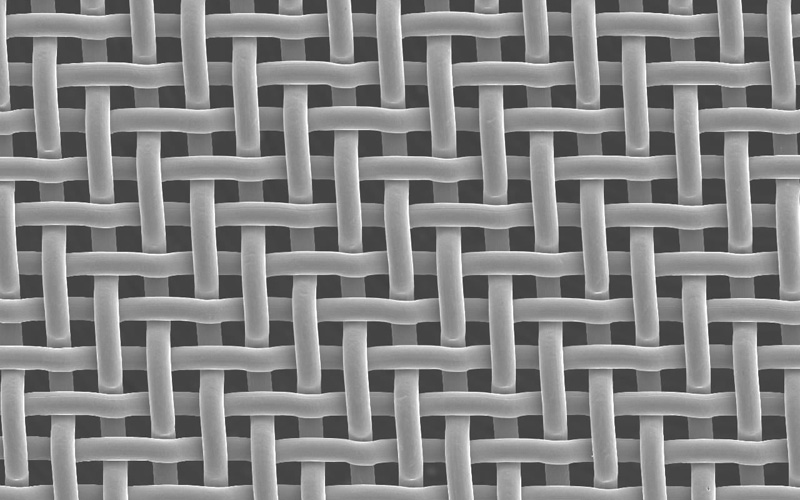

The tensile strength of these meshes has been improved beyond the BS Standard, so higher printed resolution has been achieved.

Using stainless wires of high strength and low elongation, these meshes are woven with an open ratio of 60%. Thus, the transmittance of printing paste improves.

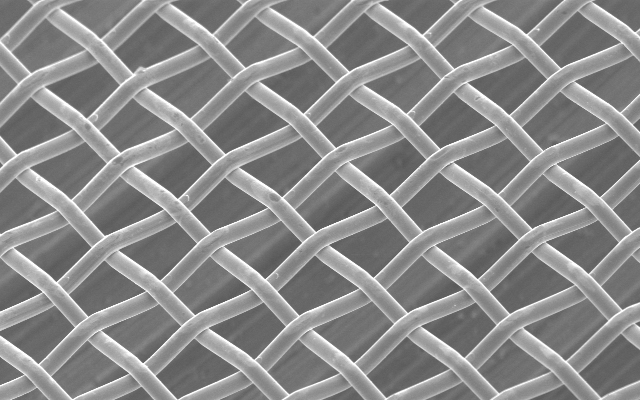

The tensile strength of HS-D meshes is 3 times greater than BS-Standard. Produces more stable and dimensional accurate print. Screen printing potential will be further enhanced.

The wires are woven into a special weaving structure which yields a mesh 3 times thicker than the wire diameter; which is suitable for Thick Deposit printing.

Solid mesh is unique structure for thicker screen printing than 3D mesh.

Woven Wire Cloth can be roll-calendering to be thinner and flatter with a special rolling mill independently developed.

Woven wires are blackened through surface treatment. It enhances printing resolution by preventing random light reflection during the UV exposure process.

Sieving and Filtration

Our Products are widely used for various fields of Filtration and Sieving applications. Higher tensile Stainless Steel Wire Mesh is excellent in durability and sieving efficiency. Nominal filtration Accuracy of Twilled Dutch 4860 mesh is about 2 to 3 microns.

Technical information

At Asada Mesh, we use technical skill honed over many years to produce wire mesh for high quality sieves and filters. We have an abundant product line of high-accuracy, highly durable, and highly efficient metal mesh which could be the solution to your needs. We will deliver such useful information going forward.

High Accuracy

Our 977 Mesh is used for the finest mesh used for sieving. It has 977 strands per inch with an opening rate of 13µ.

Mesh Opening Accuracy

For the best accuracy in sieving, the mesh opening must also be precise.

For Better Sieving

Whether it be high opening rate mesh, a certain weaving style, or something else, we can manufacture specialty mesh based on your needs.

Product Information

SV-Sieve is our standard product for filtration and sieving.

SV+α-Sieve is made of high tensile wires with high opening rate.

RO-Sieve is woven with a rectangular opening shape instead of square.

PD-&TD-Filtermedia have a unique structure where weft wires are woven at high density without any gaps between them.

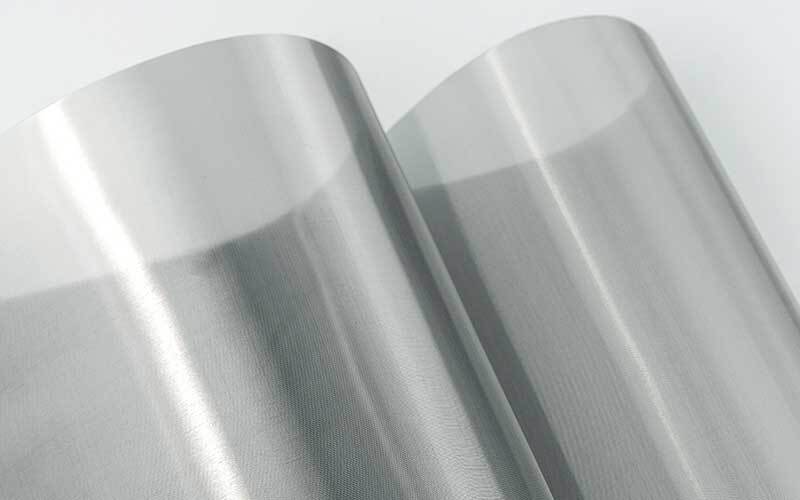

Design Mesh

Asada Mesh’s Design Mesh is a superb material woven with the artisanal skill of Kawachi cotton. At first glance it is hard to believe this mesh is metal. Its special features, non-flammable and high aesthetic value, mean our Design Mesh is used in a multitude of ways in architecture and fashion. Let us introduce you to the beauty and usefulness of metal mesh, so unlike any fabric that has come before.

Product Information

Though it is called Design Mesh, it can fulfill many different purposes. We have different types of mesh with different characteristics, so please choose based on your needs.

BASIC

Wires are thick and strong, and the mesh will keep whatever shape it is given.

SOFT

Softness incomparable to everyday metal wires, soft and flexible.

ELEGANT

Through original techniques and weaving ingenuity, this is a mesh with strong metallic luster.

SILKY

Sheer, and as fine and silky as silk.

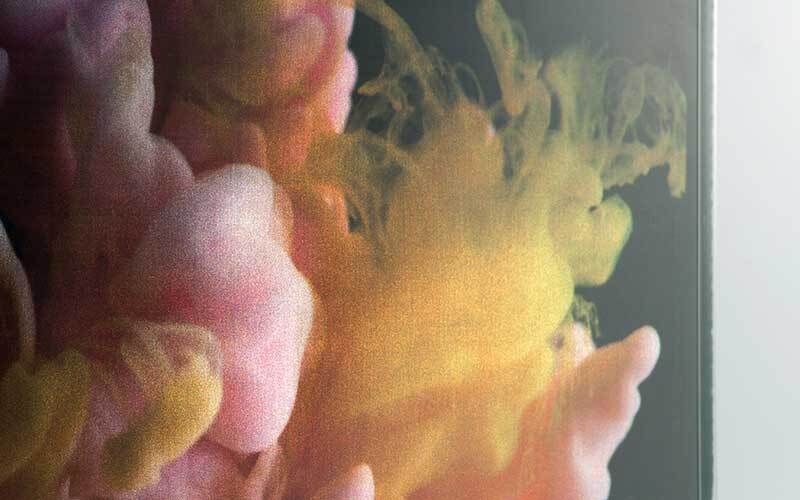

GIN MAKU

Woven with specialty techniques to minimize transparency, this mesh can be used in projection imaging.

SHINE

The surface is smoothed for a distinctive shine, this mesh has a new, polished texture.