The Backbone of Screen Mesh MechanismsRoles of Screen Mesh

- Screen Printing

- Technical Information-01

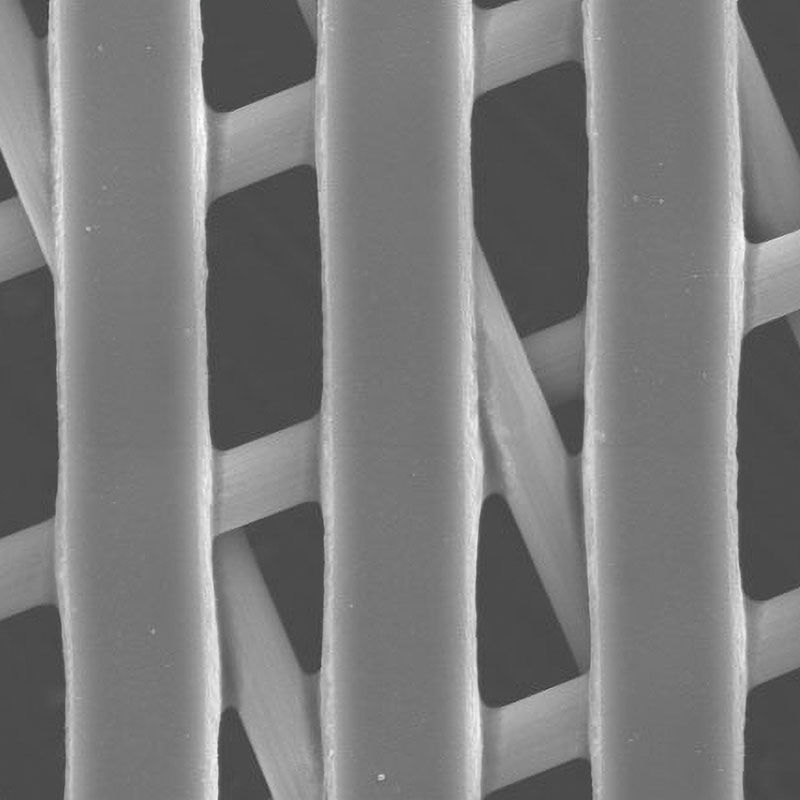

In recent years, due to the rapid improvement of elemental technology in screen printing, fine lines of 50 microns or smaller are about to be adopted in mass production in various fields. Screen printing is known for its versatility, but it is “screen mesh” that is the backbone of the technical mechanism. Here are some of the examples:

Retains Emulsion

To precisely form an image on the screen mask, it’s critical to retain the photosensitive emulsion with the plated image. As the support medium, screen mesh must have durability because the printed image will be distorted if the screen mesh is deformed.

High Tensile Strength

Screen mask and substrate follow a continuous “peel-off” during the printing process. Without stable screen tension, a clean “peel-off” is impossible. The higher the tension, the better “peel-off” that can be achieved . This improves overall printing quality.

Controlling Ink Transfer

The uniqueness of screen printing is that, “paste goes through the openings of the mesh in the screen mask”. By adjusting the opening rate or thickness of the mesh, you can control the amount of paste discharge in screen printing.

Selecting the Printing Resolution

When printing, the paste on the screen mask is spread into each opening of the screen mesh, and pushed onto the substrate by a rubber squeegee. The smaller the mesh opening, the more the paste distribution in the mesh. This helps print with finer resolution.