Learn more about our company-- our organization, our departments,

and what kind of work we do.

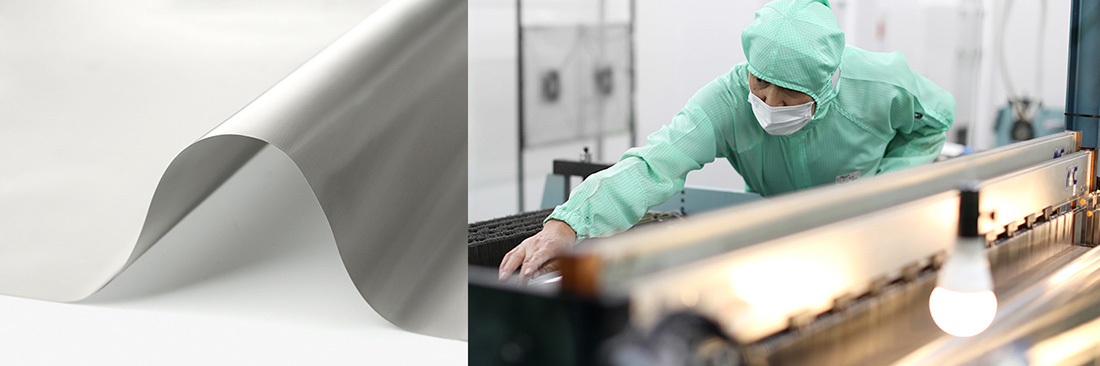

Our motto when it comes to work is “Work together as a team and strive.” It takes time and people-power to go from the weaving of ultra-fine wires to the production of stainless steel mesh. It is not something that can be done by one person alone. It is through the teamwork, mutual support, and trust between coworkers that we are able to strive in the production of excellent mesh. It is that teamwork, that mutual quest for excellence, that has kept Asada Mesh the leading company in stainless mesh. We’d love to welcome more and more people into our team.

Our wire mesh is mainly used in screen printing, but is also used in industrial powder seiving and in filtering.

Since our foundation in 1940, we have become a central supporting figure of manufacturers of electronics all over the world becasue of our specific skill in making the highest class fine mesh openings.

Pre-Production Section

In pre-production, (the processes necessary before weaving) fine wires of the weft (1/4 as thin as a strand of human hair) must be threaded through the reed, and the warp wires must be wrapped around the beam.

Weaving Section

Operators perform daily and periodic inspections as weaving progresses.

Inspection Stage

At the Kagoshima Plant, all wire mesh is inspected post-production visually, and with special instruments.

Product Processing

As soon as it is woven, mesh must be cut to customer specifications, and after another cycle of inspections, moved on to secondary treatments.

This work involves setting and adjusting the conditions of standards to machine operators and customer requirements, as well as machine maintenance and control panel maintenance.

Here, they are in charge of production and development. Improved production efficiency translates into company growth.

This is where we test and experiment with new products based on client needs. Additionaly, this department handles communication with overseas partners for joint research projects.

This department makes sure our products pass our internal inspections.

Here we use our internal software to create production orders and input data.

Here our team enters data into the computer system, and performs other administrative duties using email, phone, and in-person meetings with visitors. Their tasks also include postal sorting and various other clerical work.

We have the highest share in the world of screen printing mesh and as such, we export products everywhere, including Taiwan, South Korea, China, and the United States. We handle foreign trading, and you will be assigned to the sales team a few years after joining the company.